Robotization of anode butt cleaning

The finishing stage of anode butt cleaning, which is carried out manually, involves the use of tools such as scrapers. This manual cleaning operation is demanding, involving ergonomic issues and repetitive movements. Moreover, the effectiveness of manual cleaning can vary considerably depending on the wear and shape of the butt. To meet these challenges, Aluminerie Alouette entrusted Norda Stelo with the automation and robotization of anode butt cleaning.

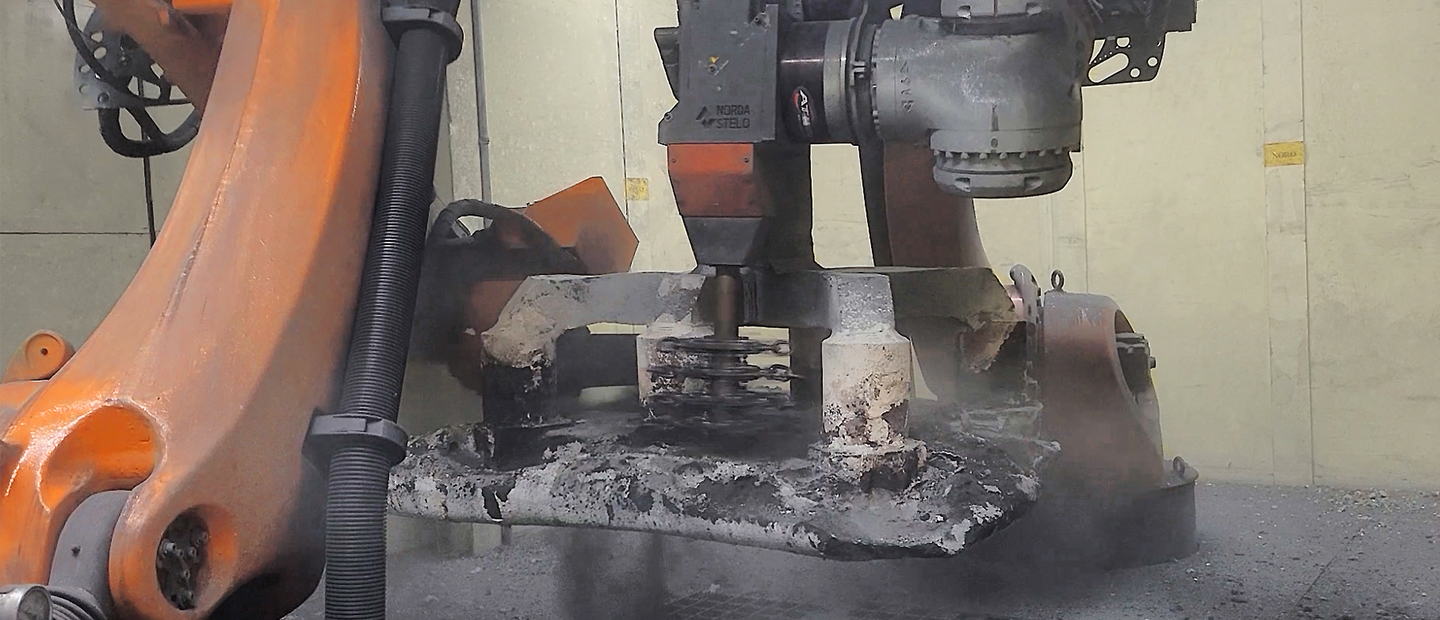

Our team then designed a robotized cell with two robots on either side of the anode to be cleaned. These robots are equipped with an arm fitted with a chain flail, capable of dislodging deposits by mechanical action. This cell has been specially designed to fit into confined workspaces. Movement and cleaning cycles are adjusted according to the configuration of deposits on the anode, thanks to specifically defined itineraries.

The project team took on the complex challenge of integrating two robots into an existing production line while continuing research and development to meet the customer’s specific requirements. In addition to improving worker health and safety by eliminating the risks associated with manual cleaning, the system also enables better removal of residues from the anodes, making them more efficient in the electrolysis process, and thus helping to reduce the carbon consumption required.

Highlights

- The robotized anode butt cleaning process represents a first in the heavy industry of aluminum.

- The robotized cell is designed for continuous use, 24/7.

- Workshop tests have validated the efficiency of the robots’ itineraries, reducing cleaning times in real-life situations.

- The project eliminates the risk of musculoskeletal injuries for operators.

Related projects

-

Technical support in reliability, and implementation of an inspection program at the Goro nickel plant

Technical support in reliability, and implementation of an inspection program at the Goro nickel plant -

Support for the implementation of the Whabouchi mining project

Support for the implementation of the Whabouchi mining project -

Environmental management for the Koniambo mining project

Environmental management for the Koniambo mining project -

Environmental and social impact assessment for the Renard diamond mining project

Environmental and social impact assessment for the Renard diamond mining project